2026 How to Choose the Best Automatic Car Wash Parts for Your Business?

Choosing the right Automatic Car Wash Parts is crucial for your business's success. Quality components can enhance efficiency and improve customer satisfaction. However, the landscape of car wash parts may seem overwhelming. With numerous options available, making the right choice requires careful consideration.

When selecting Automatic Car Wash Parts, it’s essential to assess both performance and reliability. Think about the specific needs of your car wash system. Not every part is created equal. Look for durability and ease of maintenance. These factors can save money in the long run. It’s easy to overlook the importance of compatibility with existing equipment. A mismatch can lead to costly downtime.

Reflect on your past experiences with car wash parts. Have you faced issues with certain brands or models? Learning from previous mistakes can guide your decision-making. Balancing cost and quality is a common challenge. Don’t rush the process; thorough research is key. Your choice of Automatic Car Wash Parts can ultimately define the success of your business.

Understanding the Essential Components of Automatic Car Wash Systems

When selecting automatic car wash parts, understanding the essential components is crucial. Every system relies on components like pumps, brushes, and conveyors. These parts work together to create an efficient washing process. Pay attention to the quality of materials used. Durable components lead to fewer breakdowns, saving you money over time.

Tips: Regular maintenance of parts is essential. Inspect brushes for wear and tear. A worn brush can scratch the vehicle’s surface. Check pumps frequently to ensure optimal water pressure. Underperforming pumps can lead to poor wash quality.

Also, don't overlook the importance of the chemical dispensing system. It impacts the cleaning effectiveness significantly. An effective system ensures the right amount of cleaning solution is used at all times. A poorly calibrated system may waste chemicals or provide insufficient cleaning. It’s essential to strike a balance for efficient operation and minimal waste. Gauge how these components serve your business needs. Making informed choices is key to success.

Comparison of Key Components in Automatic Car Wash Systems

This chart illustrates the importance ratings of various components in automatic car wash systems, providing insights for selecting the best parts for your business.

Evaluating the Durability and Reliability of Car Wash Parts

When choosing automatic car wash parts, durability and reliability are crucial. Data estimates that replacing inefficient parts can cost businesses over $10,000 annually. A reliable part reduces downtime and maintenance costs, making it essential for operational efficiency. Unfortunately, many operators overlook these aspects, focusing instead on initial costs, which can be misleading.

Consider material quality. Parts made from high-grade stainless steel or corrosion-resistant materials tend to last longer. A supplier's warranty reflects their confidence in the product's durability. Look for parts with at least five years of warranty. Understand that cheaper materials might lead to frequent replacements. This impacts service continuity and customer satisfaction.

Tip: Always check user reviews and testimonials. Real-world feedback can reveal hidden issues. Inspect parts upon delivery for any visible defects.

Proper installation is non-negotiable. Even the best parts perform poorly if installed incorrectly. Spend time on training staff. Inadequate knowledge can lead to mistakes. Regular maintenance should also be a priority. Schedule inspections to catch wear before it escalates. All these factors contribute significantly to an automatic car wash's long-term success.

Exploring Different Types of Automatic Car Wash Equipment

When exploring automatic car wash equipment, various types stand out. Each has its unique features, catering to different business needs. Touchless systems use high-pressure water jets and detergents to clean vehicles. They minimize surface contact, reducing wear on the car's finish. However, they may not remove tough grime effectively, leaving some customers unsatisfied.

On the other hand, traditional friction units employ soft cloths or brushes to scrub the vehicle. They provide a thorough clean but require regular maintenance. Brushes can wear down over time, leading to inconsistent cleaning. Additionally, they can cause minor scratches if not properly maintained. Businesses should weigh these factors when selecting equipment.

Considering customer expectations is crucial. An effective car wash doesn’t just clean; it leaves a good impression. Investing in high-quality equipment is essential. However, don’t overlook the importance of staff training. Employees must understand how to operate the machines properly. This ensures the wash runs smoothly and consistently meets customer needs. Balancing equipment choice with proper training leads to a more successful business.

Cost Analysis: Budgeting for Quality Car Wash Components

When budgeting for quality car wash components, it’s essential to analyze costs carefully. The parts you select can significantly impact your operational efficiency. Start by researching the durability and reliability of various parts. Investing in higher-quality components often leads to fewer breakdowns and maintenance issues. However, this can strain your initial budget.

Consider the long-term savings associated with quality parts. Cheaper options may save you money upfront but can lead to frequent replacements. This could raise costs over time. Assessing the total cost of ownership can provide clarity. Calculate how much downtime affects your revenue. Sometimes, your choice reflects immediate savings rather than overall value.

Don’t forget to factor in installation costs. Some parts require specialized skills. This can inflate your budget unexpectedly. It’s worth reflecting on your overall business strategy and future growth. Will you need more advanced options as your business expands? Balancing quality with budget constraints can be challenging but necessary for sustainability.

Maintenance Tips for Extending the Life of Car Wash Parts

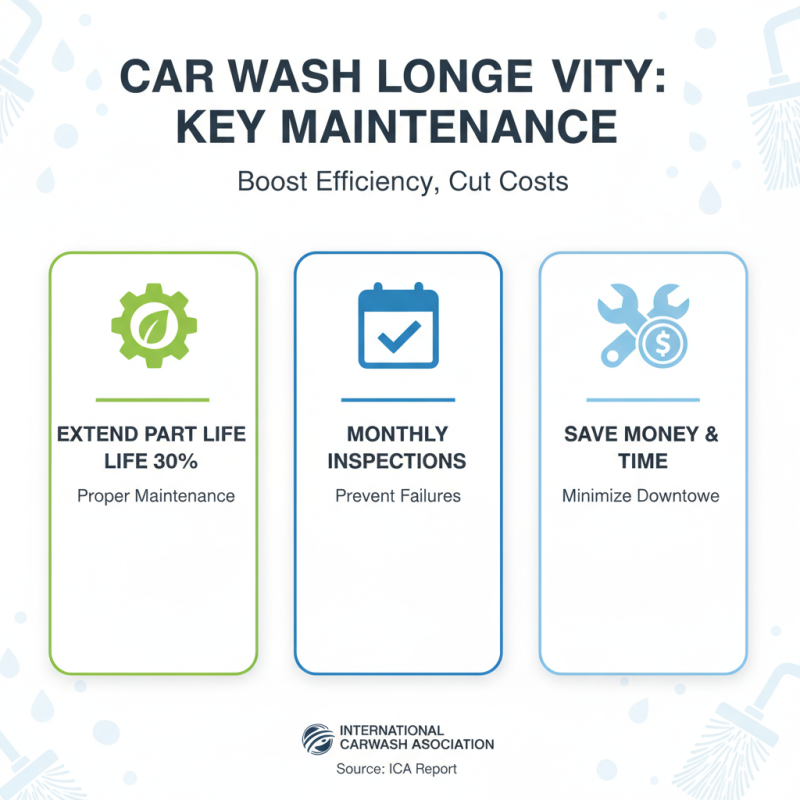

Maintaining the longevity of automatic car wash parts is essential for minimizing costs and ensuring efficiency. A report by the International Carwash Association states that proper maintenance can extend the life of wash components by 30%. Regular inspections should be scheduled at least once a month. This can help identify worn-out parts before they cause significant failures.

It’s crucial to regularly clean the nozzles and filters. Clogged parts can reduce water pressure, leading to ineffective washes. According to industry data, 20% of downtime in car wash operations comes from neglected maintenance. Keeping a detailed log of maintenance activities helps track wear and tear over time.

Lubrication of moving parts should not be overlooked. Insufficient lubrication can lead to friction and damage. Some operators neglect this step, resulting in costly repairs. Moreover, using high-quality soap and detergents helps to minimize buildup on components. This protective measure can significantly reduce maintenance frequency. Being proactive saves both time and money in the long run.

Related Posts

-

Advantages of Using Automatic Car Wash Parts for Enhanced Efficiency

-

Complete Guide to Essential Automatic Car Wash Parts for 2025

-

10 Reasons Why Best Machine Car Wash is the Ultimate Choice for Your Vehicle

-

2025 Top 10 Car Wash Machines You Need for a Sparkling Clean Vehicle

-

Top Tips for Using a Self Car Wash Machine Effectively?

-

Why You Need a Car Wash Machine for Your Vehicle Maintenance